Hess has made significant investments in shale energy operations in the Bakken Formation in North Dakota, one of the premier U.S. tight oil plays.

We recognize that some stakeholders have concerns about the potential effects of shale energy operations on the environment, public health and safety. At Hess, the practices we use are well established and have been employed in conventional oil and gas development for many years.

We aim to develop our resources responsibly and with minimal impact, and, as discussed in the Social Responsibility section of our 2022 Sustainability Report, we seek to identify and address stakeholder feedback to facilitate performance improvements and enhance our license to operate. All of our assets undergo several stages of detailed, activity-based risk assessments during their appraisal, capture, development, production and abandonment. These multidisciplinary risk assessments enable us to identify potential mitigation measures to help protect the environment, the communities in which we operate and the safety of our workforce. Further, our enterprise risk management process, discussed in the How We Operate section of our 2022 Sustainability Report, includes the identification and ranking of environmental considerations as well as technical review and value assurance activities. We also perform numerous environmental, health and safety audits or assessments on an annual basis.

Well Integrity

Maintaining well integrity – that is, installing and sustaining physical barriers to prevent the uncontrolled or unintended release of oil, natural gas or produced fluids to the surface or to underground aquifers – is fundamental to protecting the environment and the health and safety of our workforce and the communities where we operate.

We take a lifecycle approach to integrity for all Hess wells. While hydraulic fracturing processes occur several thousand feet below the earth’s surface, wellbores must often pass through groundwater bearing zones at shallower depths. Before designing or constructing wells, we first investigate the depth and lateral extent of any underground fresh water present so that the well can be drilled and completed in a way that protects groundwater resources and conforms to regulatory requirements and Hess standards. We then identify the appropriate barrier systems for maintaining integrity throughout the well lifecycle. These barriers are established during construction and maintained and monitored through production, then new barriers are added during abandonment as needed. If at any point during the well lifecycle a barrier becomes compromised, we will repair or replace it so that we maintain two barriers at all times.

Our enhanced well integrity management system, which has been integrated into the Hess Operational Management System, defines our organizational structure for managing well integrity and provides a framework of technical standards and procedures for each stage of the well lifecycle and associated field activity.

Our global standards for well integrity specify requirements for designing, constructing and operating Hess wells and identifying and assessing elements critical to well integrity, such as barriers designed to prevent or stop the uncontrolled flow of well fluids. They also outline the criteria for the installation, verification, maintenance and operating limits of barriers used through the lifecycle of the well.

We continue to advance our well integrity management system based on ongoing reviews of field activity and will reassess integrity risks throughout the well lifecycle if we identify or anticipate any material changes to a well’s design, construction or operation. We are also continuing to improve documentation, data collection and key performance indicator reporting and to enhance the chain of communication as responsibility for the well passes from one Hess team to another.

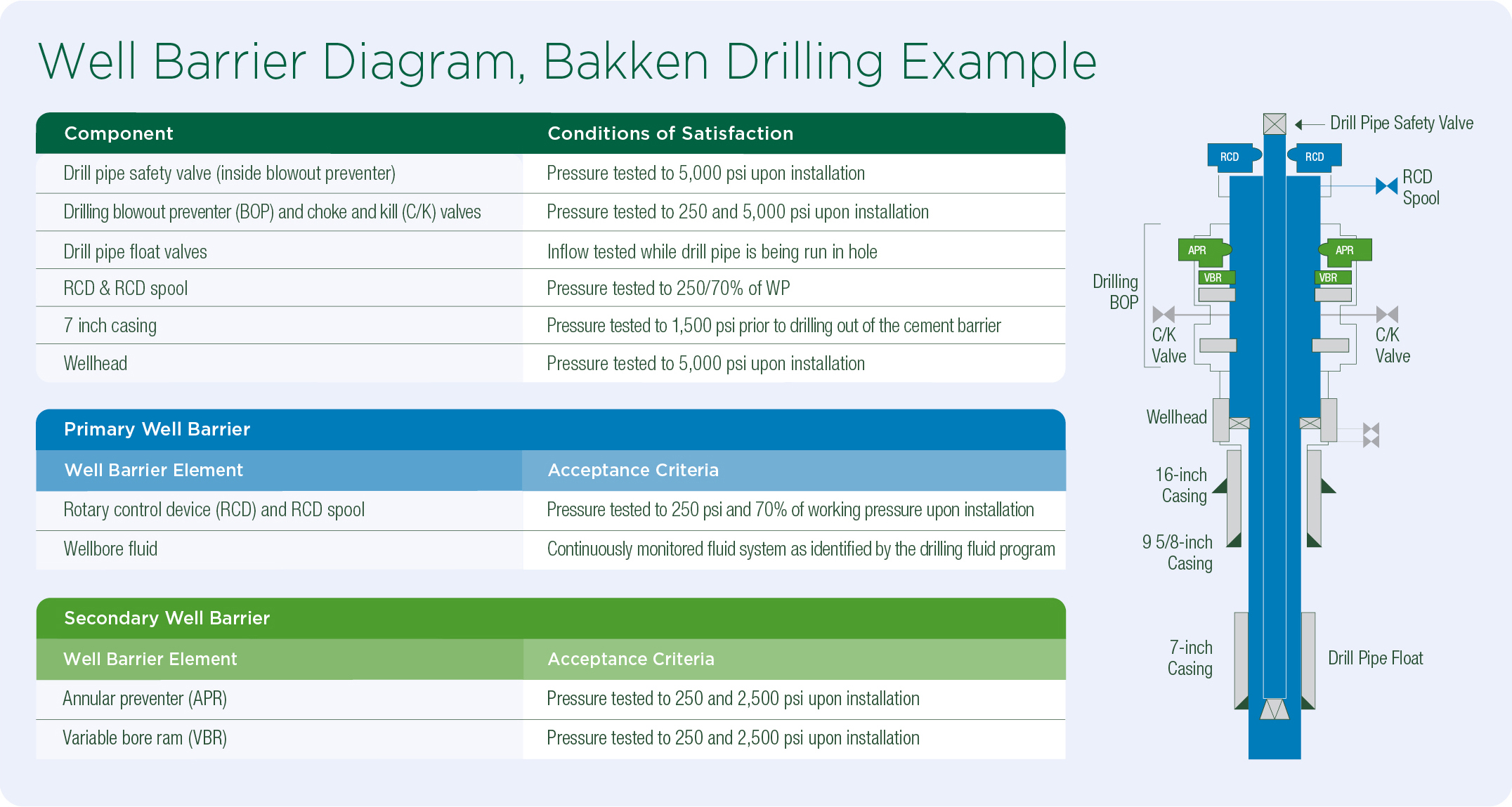

Well Barrier Design, Construction and Monitoring

Our standards require the completion of a detailed well barrier diagram before undertaking any activities in the field. Where applicable, we submit our design casing and cementing plans in applications for well construction permits, which must be reviewed and approved by regulators. Well designs can vary from asset to asset due to differences in geologic formation, the management of drilling risks and the application of technology. To reinforce well integrity, our drilling process for new shale wells involves lining wellbores with multiple layers of steel pipe encased in cement to depths well below the deepest freshwater zones. Specifically:

- A surface casing is installed from the surface to below the lowest known freshwater zone and then cemented in that interval to isolate the freshwater zone, thereby creating a physical barrier between the materials in the well and the strata containing the groundwater being protected.

- Inside the surface casing, another casing is installed and cemented in place, and an acoustic cement bond log is employed to confirm that the cement barrier meets applicable regulatory requirements.

- The well completion is performed through the 7 inch casing string with a 4.5 inch liner or through a long string production casing from the surface to total depth of the well. Prior to installation, the casing is evaluated using ultrasonic inspection tools to determine compliance with our rigorous design criteria. In addition, we utilize various well logging techniques that either meet or exceed applicable regulatory requirements to evaluate cement and casing integrity. The log data, in combination with advanced wellbore stress modeling, help us to ensure that the appropriate steps are taken to protect wellbore integrity during fracturing activity.

- Once completed, all of our wells have, at a minimum, a 300 pound per square inch analog pressure gauge installed between the surface intermediate and production casings to detect overpressure in the well. We have upgraded our wells that have a low top of cement by installing digital gauges that are connected to our supervisory control and data acquisition system.

- In an effort to prevent any potential fracture stimulation interference – that is, stimulating one well and having it result in hydraulic communication in nearby wells – existing nearby offset oil and gas wells are shut in during fracturing activity. In addition, either the wellhead systems in nearby wells are tested prior to being shut in or additional equipment is installed on wellheads that can safely operate within proper distances.

- During hydraulic fracturing, procedures are in place to operate surface and downhole equipment within its design parameters.

We maintain and monitor well integrity from the initial drilling phase through plugging and abandonment. For example, we pressure test barriers and well components during construction, after first utilizing computer models to confirm we will not overpressure the component during testing. In addition, we use techniques such as well logging that either meet or go beyond applicable regulatory requirements to validate correct cement placement between the production casing and the formation before completing our wells. Onshore, we routinely monitor annular pressures as an indicator of well integrity issues. At the end of a well’s life, we follow the same integrity focused process to permanently plug and abandon wells in compliance with applicable Hess, regulatory and industry standards.

Induced seismicity from hydraulic fracturing or underground injection wells has not been an issue for our operations in North Dakota. Hess drilled 78 wells and hydraulically fractured 69 wells in the Bakken region in 2022, with none experiencing a Level 1 well control incident and only one undergoing a Level 2 incident as defined by the International Association of Oil & Gas Producers. No hydrocarbons were released to the surface as a result of the Level 2 incident. We follow stringent protocols to avoid any releases to the environment and to address any releases that do occur. For more information on our spill prevention program, see the Environment section of our 2022 Sustainability Report.

Protection of Water Quality

Hess implements a variety of controls to protect water resources. Our well pads and aboveground equipment use secondary containment during drilling operations to minimize impacts from any loss of primary containment (LOPC) events. We have processes and procedures to respond to an LOPC event that aim to quickly control, contain and mitigate impacts. We also incorporate measures into our construction design to prevent stormwater from entering the well pad and to control precipitation that falls within an operating area to help prevent runoff from leaving the pad.

We employ closed loop containment systems for drilling fluids, which further reduce the risk of LOPC events. These systems also provide efficiency in controlling waste volumes, since liquids and cuttings can be better separated for improved waste management and disposal. We store flowback and produced water in closed tanks.

The North Dakota Department of Environmental Quality (DEQ) operates and routinely monitors a regional network of groundwater quality monitoring wells. The network is composed of approximately 125 wells across 21 aquifers. The DEQ samples wells every 18 months for benzene, toluene, ethylbenzene and xylene (BTEX), total petroleum hydrocarbons, metals and other water quality parameters. We believe these activities afford impacted parties a level of protection while promoting transparency and stakeholder engagement. We also maintain a separate groundwater monitoring program for Hess Midstream’s produced water disposal wells.

Water Use

Hess utilizes the World Resources Institute’s Aqueduct Water Risk Atlas to assess water scarcity and associated risks. Using the default settings in this tool, we find that the majority of our North Dakota operations are located in the low to low–medium risk category. However, we understand the importance of managing water resources responsibly and continue to evaluate our operations for potential opportunities to improve our water performance.

In North Dakota, we use water for several purposes. A few 2022 statistics help provide perspective on our water use profile in the state:

- We used approximately 3,356,000 cubic meters of fresh water for hydraulic fracturing and approximately 147,000 cubic meters of fresh water for well maintenance.

- Hydraulic fracturing accounted for 85% of our freshwater use and 84% of our total water use.

- We reused 4% of our total produced water. By reusing approximately 293,000 cubic meters of produced water, we were able to offset freshwater use by that same amount.

- We currently do not reuse flowback water from hydraulic fracturing. Flowback water represented approximately 4% of our total wastewater disposal in North Dakota.

Currently, only fresh water is used for our hydraulic fracturing activity. In 2022, approximately 41% of the fresh water we used for hydraulic fracturing was sourced from surface water (primarily Lake Sakakawea), with the remainder sourced from groundwater wells.

Wastewater Management

Produced water is the primary source of wastewater in our Bakken operations. In total, approximately 6,772,000 cubic meters of produced water and flowback water were managed via deep well disposal in North Dakota in 2022, a decrease of approximately 2% compared with 2021. We continued our efforts to identify additional opportunities to use produced water in our hydraulic fracturing operations in 2022.

Produced water is isolated from surface water and groundwater resources throughout its lifecycle. Once this water has been extracted from below the surface, it is contained in aboveground processing equipment and storage tanks that have secondary containment barriers; Hess does not use open impoundments or pits for wastewater storage. Our tanks and processing equipment have corrosion control procedures in place and are subject to weekly visual integrity inspections by reliability operators. This is in addition to the optical gas imaging and audible, visual and olfactory inspections conducted under our leak detection and repair program in North Dakota, which covers our operations in that state, including storage equipment used for wastewater management. The use of closed tanks for produced water and residual drilling waste helps mitigate potential exposure to the environment and wildlife.

Naturally Occurring Radioactive Material

Shale, petroleum and natural gas deposits often occur in aquifers that contain produced water (also referred to as brine or salt water) and that may also contain naturally occurring radionuclides, which are referred to as naturally occurring radioactive material (NORM). Radionuclides, along with other minerals that are dissolved in the brine, separate and settle out, forming various wastes at the surface, including:

- Mineral scales inside pipes

- Sludges/sediments

- Contaminated equipment or components

Because the extraction process concentrates NORM and brings it to the surface, these wastes are often classified as technologically enhanced naturally occurring radioactive material (TENORM). More information on TENORM can be found on the U.S. Environmental Protection Agency’s (EPA) website.

At Hess’ Bakken operations, NORM and TENORM are generally found during three key activities: production equipment cleanout, which takes place when a buildup of sludge occurs and impacts the operation of equipment; equipment replacement (e.g., flanges, valves and piping); and facility retirement, when the aboveground assets are removed from the operational location for disposal or for storage for reuse.

Trained personnel conduct cleanup activities and surveys to identify the presence of NORM/TENORM at Hess locations. If NORM/TENORM is identified at actionable levels, the North Dakota business unit’s waste management procedure is followed to properly label, store, transport and dispose of these materials. NORM/TENORM wastes are disposed at Hess approved facilities, which have been audited by Hess for compliance with our requirements and applicable regulations.

To date, no actionable levels of NORM/TENORM have been identified in our produced water. Therefore, it is either reinjected into deep wells for disposal or reused for well maintenance.

For more information on our waste management program, see the Environment section of our 2022 Sustainability Report.

Hydraulic Fracturing Fluid Composition

Hydraulic fracturing fluid is predominantly composed of water, with proportionally small volumes of proppant and chemical additives. Proppants are solid materials used to hold open geologic formations, which is necessary for oil and natural gas to flow into a well. Since 2016, we have used sand as proppant instead of ceramic materials. The chemical additives in fracturing fluids are necessary for specific purposes, such as reducing friction, exterminating bacteria and inhibiting corrosion and scale deposits. We use only two additives, a friction reducer and a more environmentally favorable surfactant, for all new hydraulically fractured wells in North Dakota.

We know that some stakeholders are concerned about the chemical composition of hydraulic fracturing fluid. We do not use BTEX or diesel in our hydraulic fracturing fluids. All of our downhole chemicals are disclosed on the FracFocus reporting website (www.fracfocus.org). While respecting laws and commercial confidentiality obligations that allow our service providers to preserve the confidentiality of their fracturing fluid formulations, we encourage transparency in chemical use and disclosure.

Air Emissions

In our shale energy operations, regulated emissions occur during flowback and production. When technically feasible, these emissions are collected and directed to a pipeline for gathering and processing. Where pipeline availability is constrained, flaring may occur.

See the Climate Change and Energy section of our 2022 Sustainability Report for more information on greenhouse gas (GHG) emissions and the Environment section for a discussion of non-GHG air emissions.

Land Use

We seek to minimize land use and reduce the number of well sites needed to develop our acreage. In North Dakota, this can be achieved by implementing multiwell pad drilling – that is, multiple wells on a single well pad with shared surface facilities. We use geographic information systems when siting these facilities to identify ways to minimize impacts on the environment and local communities. In addition, we have implemented a detailed protocol to help steer our development teams through a process to identify opportunities to minimize impacts to the environment, including those related to land utilization.

Transportation Impacts

We are sensitive to stakeholder concerns about increased trucks on the road in areas of high drilling activity. In North Dakota, we have participated in multistakeholder initiatives aimed at minimizing impacts on public roads and traffic congestion. We have also collaborated with community partners and state officials in North Dakota to promote adequate infrastructure funding in an effort to improve traffic safety and support road maintenance.

We continue to use piping, rather than trucks, to transfer fresh water for completions at our North Dakota business unit. In 2022, nearly all the water used for our well completions in North Dakota was transferred by piping – this amounted to approximately 21.1 million barrels, which offset 150,700 truck deliveries. In addition, we completed infrastructure projects that transferred 5.3 million barrels of oil and 6.5 million barrels of produced water by pipeline instead of trucks, eliminating approximately 84,300 truck deliveries.

Furthermore, the Hess completions team uses sand handling systems for delivering proppant sand to all Hess wells that are fractured in North Dakota. During traditional truck unloading, blowers blast sand out of the truck, spreading dust. Sand handling systems are generally enclosed and use gravity to transfer sand from the container to the conveyor, eliminating the need for blowers. These systems also allow for significant volumes of sand to be pre-staged on location, allowing for more efficient truck management during fracturing operations.

Crude-by-Rail Safety

Improving crude-by-rail safety is a shared effort among railroads, tank car manufacturers and owners, regulators and shippers. At Hess, we are committed to doing our part to minimize the potential risks involved. Hess encourages the adoption of a holistic approach to rail safety that is science based and addresses accident prevention, mitigation and emergency response capabilities.

We continue to work with local, state and national governmental agencies, the oil industry, tank car manufacturers and owners, and the railroads to facilitate the safe transportation of crude oil and other petroleum products. We are also actively engaged in industry efforts focused on further improving the safety of rail crude oil transport, and our interests in this area are represented on the American Petroleum Institute’s Rail Policy Committee, the Committee on Federal Relations and the Midstream Strategies Subcommittee.

The Tioga Rail Terminal (TRT) is operated by Hess Midstream. Hess Midstream’s fleet of 550 crude oil tank cars was constructed to meet the most recent DOT-117 standards for newly constructed tank cars. A combination of Hess Midstream owned tank cars, leased tank cars used by Hess subsidiaries and third party rail throughput makes up the activity at the TRT.