Occupational Safety

Hess emphasizes a culture of ownership in occupational safety by empowering workers and giving them the responsibility to identify and mitigate potential risks relevant to their work activities. We manage occupational safety by utilizing the Hess Safety Improvement Framework, which has four key components:

- Safety culture: We continue to build a safety culture that emphasizes a worker centered, collaborative approach and enables learning from both incidents and successful events.

- Procedures, processes and tools: We drive improvements in safety performance through procedures, processes and tools including the Hess Rules, which are universal, mandatory safety requirements for our workforce; our global EHS standards; and a three tiered assurance process.

- Workforce engagement: We engage our workforce on safety and address key learnings through field visits by our Board of Directors and senior leadership, safety observations and joint Hess-contractor safety committees.

- Performance measures: We utilize both leading and lagging indicators and include key enterprisewide safety metrics in our annual incentive plan formula for executives and employees.

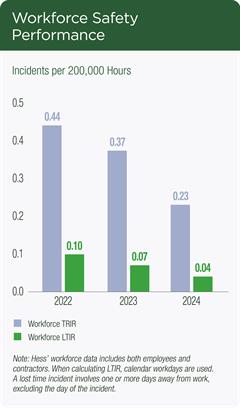

In 2024, we achieved a 38% reduction in our workforce total recordable incident rate (TRIR). We also achieved a 43% reduction in our workforce lost time incident rate (LTIR) compared to 2023. No employee or contractor fatalities occurred during 2024.

We continued our collaboration with contractors to share learnings, deploy asset specific safety improvement plans and reinforce safety expectations, culture and procedures across our operations in 2024, which supported our year over year improvement.

Hess’ enterprisewide annual incentive plan metrics include a target aimed at maintaining our severe and significant safety incidents (SSSIs) rate, with a stretch target of a 10% reduction year over year. In 2024, we achieved our stretch AIP target, with a 28% reduction. As part of our SSSI rate, we track near miss incidents that have the potential to result in severe consequences, as well as incidents that result in an actual consequence, including Tier 1 and 2 process safety events and OSHA recordable incidents. We require that near miss incidents be reported internally and recorded in our incident management system based on actual and potential consequences.

Process Safety

The aim of Hess’ process safety program is to prevent the unplanned or uncontrolled loss of primary containment of any material, including materials that are nontoxic and nonflammable (e.g., steam, nitrogen, compressed air), that could result in an incident such as injury, fire, explosion, toxic release or environmental impact. Our program supports our compliance with regulatory requirements including, where applicable, those of the U.S. Occupational Safety and Health Administration’s Process Safety Management, the U.S. Environmental Protection Agency’s Risk Management Program and the U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration.

We focus on understanding and identifying key points within process safety systems that could impact asset integrity and the safe and proper operation of equipment. In particular, we address the following:

- Design integrity: Reducing risks in the design and construction of facilities

- Technical integrity: Inspecting, testing and maintaining hardware and software barriers

- Operational integrity: Working within operational design limits

Our approach to process safety involves identifying, managing and mitigating risks across Hess operations. We do this by raising awareness of risks among our workforce, providing strong safety leadership and maintaining a commitment to continuously improve our process safety procedures, systems and standards. Over the past several years we have been working to address process safety risk through enhancements to our integrity management program and assessment of barrier health at our assets globally. Our efforts have centered on integrity critical equipment (ICE), which includes barriers and safeguards that prevent or mitigate process safety events through detection, isolation, containment, control or emergency preparedness and response within our facilities.

We established ICE performance standards, which set specific requirements and criteria for inspections and tests to help ensure ICE barriers are effective. We have been increasing the number of ICE inspections, tests and performance standard assurance reviews each year. In 2024, we achieved 100% completion of all safety critical equipment maintenance and corrective work orders with performance standards in our work order system, surpassing our target of 95% in the Hess enterprisewide annual incentive plan.

In 2024, we experienced three Tier 1 process safety events and nine Tier 2 process safety events, representing a 40% and 25% reduction year over year, respectively.. We completed investigations and root cause analyses for all Tier 1 and 2 PSEs, and we are implementing appropriate corrective actions to help prevent similar incidents in the future.

Emergency Preparedness and Response

Hess’ emergency preparedness and response program, which is formalized in HOMS, outlines our approach to responding to actual or potential injuries to people, spills and releases to the environment, damage to our assets and impacts to the company’s reputation – in that order of priority. We use a three tiered approach to plan for and respond to emergencies that integrates communication and response actions across our organization, from our corporate level Incident Support Team in Houston to asset level Incident Management Teams and facility level emergency response teams. This system also helps ensure that standards, plans, information and resources work efficiently so that we understand and address the specific needs of the situation at hand.

Hess’ emergency preparedness and response program, which is formalized in HOMS, outlines our approach to responding to actual or potential injuries to people, spills and releases to the environment, damage to our assets and impacts to the company’s reputation – in that order of priority. We use a three tiered approach to plan for and respond to emergencies that integrates communication and response actions across our organization, from our corporate level Incident Support Team in Houston to asset level Incident Management Teams and facility level emergency response teams. This system also helps ensure that standards, plans, information and resources work efficiently so that we understand and address the specific needs of the situation at hand.

Preparedness at Hess involves our emergency response organization, engagement with officials and communities, emergency facilities and response plans. We also maintain relationships with mutual aid and emergency response organizations at the local, regional and global levels.

To continue to improve our emergency preparedness and response, we conduct regular exercises, drills and trainings for our employees, contractors, mutual aid and emergency response organizations and other key stakeholders. Emergency preparedness and response exercises help define and clarify roles, responsibilities and resources. These exercises range from workshops for drafting emergency response plans to full scale exercises during which we activate our emergency response organization.

Emergency preparedness and response drills focus on equipment deployments and notifications and test components of our emergency preparedness and response plans. In equipment drills, personnel deploy emergency equipment such as booms. In notification drills, personnel practice the communication protocols required in case of an emergency.

Trainings help us continue to develop competencies and maintain our capabilities.

Continuous improvement is an essential element of our Emergency Preparedness and Response Standard. It provides guidance for incorporating lessons learned from incidents and exercises into our preparedness planning, training and future exercises. We conduct after-action reviews for all incidents, drills and exercises and develop improvement actions that are assigned to individuals with specific due dates and tracked in our internal incident reporting system.

Contractor Management

Contractors are essential to Hess, constituting approximately 71% of our total workforce hours and performing key tasks throughout our operations. Our approach to managing contractors – from prequalification to ongoing engagement to assurance – is formalized in Element 6 of HOMS. For more information, see our Supply Chain website and the Hess Supplier Network.