Occupational Safety

Hess emphasizes a culture of ownership in occupational safety by empowering workers and giving them the responsibility to identify and mitigate potential risks relevant to their work activities.

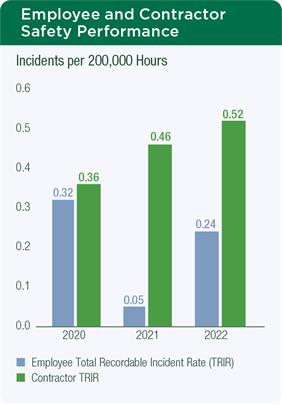

Our safety performance was mixed in 2022, with good overall performance in our offshore assets but an increase in incidents in our Bakken operations including two tragic contractor fatalities in separate incidents that involved heavy equipment movement. As a result, after having reached a six year low in our severe and significant safety incident rate in 2021, it increased by 86% in 2022. Our workforce total recordable incident rate increased by 40% compared with 2021. We experienced a 19% decrease in our lost time incident rate, year over year.

Hess leadership and teams across Hess have been collaborating with our contractors to share learnings, deploy asset specific safety improvement plans and reinforce safety expectations, culture and procedures across our operations.

Process Safety

The aim of Hess’ process safety program is to prevent the unplanned or uncontrolled loss of primary containment of any material, including materials that are nontoxic and nonflammable (e.g., steam, nitrogen, compressed air), that could result in an incident such as injury, fire, explosion, toxic release or environmental impact.

We focus on understanding and identifying key points within process safety systems that could impact asset integrity and the safe and proper operation of equipment. In particular, we address the following:

- Design integrity: Reducing risks in the design and construction of facilities

- Technical integrity: Inspecting, testing and maintaining hardware and software barriers

- Operational integrity: Working within operational design limits

Our approach to process safety involves identifying, managing and mitigating risks across Hess operations. We do this by raising awareness of risks among our workforce, providing strong safety leadership and maintaining a commitment to continuously improve our process safety procedures, systems and standards.

Our approach to process safety involves identifying, managing and mitigating risks across Hess operations. We do this by raising awareness of risks among our workforce, providing strong safety leadership and maintaining a commitment to continuously improve our process safety procedures, systems and standards.

Compared with 2021, 2022 Tier 1 PSEs remained flat and Tier 2 events increased. We completed investigations and root cause analyses for all Tier 1 and 2 PSEs, and we are implementing appropriate corrective actions to help prevent similar incidents in the future.

Our program supports our compliance with regulatory requirements including, where applicable, those of the U.S. Occupational Safety and Health Administration’s Process Safety Management, the U.S. Environmental Protection Agency’s Risk Management Program, and the U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration, and includes these certifications.

Emergency Preparedness and Response

Hess’ emergency preparedness and response program, which is formalized in HOMS Element 9, outlines our approach to responding to actual or potential injuries to people, spills and releases to the environment, damage to our assets and impacts to the company’s reputation – in that order of priority. We use a three tiered approach to plan for and respond to emergencies that integrates communication and response actions across our organization – from our corporate level Incident Support Team in Houston to asset level Incident Management Teams and facility level emergency response teams. This system also helps ensure that standards, plans, information and resources work efficiently so that we understand and address the specific needs of the situation at hand.

Hess’ emergency preparedness and response program, which is formalized in HOMS Element 9, outlines our approach to responding to actual or potential injuries to people, spills and releases to the environment, damage to our assets and impacts to the company’s reputation – in that order of priority. We use a three tiered approach to plan for and respond to emergencies that integrates communication and response actions across our organization – from our corporate level Incident Support Team in Houston to asset level Incident Management Teams and facility level emergency response teams. This system also helps ensure that standards, plans, information and resources work efficiently so that we understand and address the specific needs of the situation at hand.

Preparedness at Hess involves our emergency response organization, engagement with officials and communities, emergency facilities and response plans. We also maintain relationships with mutual aid and emergency response organizations at the local, regional and global levels.

Contractor Management

Contractors are essential to Hess, constituting approximately 70% of our total workforce hours and performing key tasks throughout our operations. Our approach to managing contractors – from prequalification to ongoing engagement to assurance – is formalized in Element 6 of the Hess Operational Management System.