Our commitment to safeguarding the environment is central to our company and embedded in the Hess Values. With oversight from our Board of Directors and executive leadership, we strive to continuously address risks across a range of environmental resources and improve our performance. This work is rooted in the Hess Operational Management System, which guides our day to day efforts, and we dedicate significant staff and resources to help ensure compliance with environmental laws and regulations, international standards and voluntary commitments. At both the enterprise level and the asset level, we have developed specific goals and targets to drive and track improvements in our environmental performance – some of which are integrated into our enterprisewide annual incentive plan (AIP).

See our Key Sustainability Metrics where we disclose our five year performance data for key environmental metrics.

Water Management

Responsible water management is a primary focus of environmental efforts at Hess and continues to be one of our key sustainability issues. The communities and ecosystems where we operate depend on water to thrive, and we know that our operations have the potential to impact this essential resource. These possible impacts would primarily be through our use of fresh water, however, impacts to water quality could also occur due to well integrity issues, spills or discharges. We continue to employ a risk based, lifecycle approach to managing water use through which we carefully assess and work to mitigate any potential impacts on water resources in both our onshore and our offshore operations.

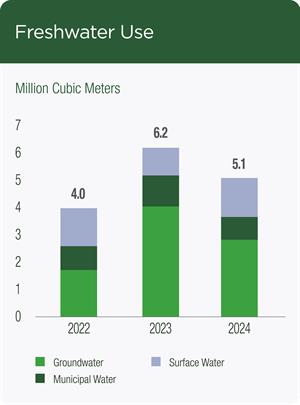

Our freshwater use predominantly occurs in our onshore upstream operations during drilling and completions activities and in cooling in midstream gas processing. We also use fresh water in our offshore operations for some drilling activities and to supply potable water to personnel, though we primarily meet these needs by converting seawater to fresh water through reverse osmosis.

As our operational profile and practices continue to evolve, we remain committed to identifying our potential impacts related to freshwater use and evaluating opportunities to reduce freshwater use in our operations. As part of this commitment, we updated our water stressed resource analysis in 2024 for the Bakken region – our only onshore operation and the primary region where we use fresh water – using the World Resources Institute’s Aqueduct Water Risk Atlas. This analysis confirmed that we are not operating in any areas of high baseline water stress and the potential for us to impact fresh water is therefore limited.

In addition to assessing the current state of water stress where we operate, we look at the risk exposure of our assets under the Representative Commitment Pathway scenarios from the Intergovernmental Panel on Climate Change to assess how climate change may impact future water availability and water stress in areas where we operate. Our approach to monitoring physical risks related to climate change is described on our Carbon Asset Risk Assessment and Reputational and Physical Risk Assessments webpages.

A key component to reducing our freshwater use is the reuse of produced water, nonpotable water that is released from underground formations along with produced oil and natural gas. Our ability to reuse produced water varies based on the geology of the formation, production levels and changes in hydraulic fracturing technologies, among other factors.

In 2024, Hess’ total freshwater use decreased by 18% compared with 2023, which can be primarily attributed to improvements made in our hydraulic fracturing design in the Bakken, which use less water for well completions. We reused approximately 9% of our freshwater in 2024.

Spill Prevention

The prevention of releases is one of Hess’ key sustainability issues. We maintain spill preparedness and response plans and conduct emergency response exercises at each of our assets. To support a swift and effective response to any loss of primary containment (LOPC) event, we maintain strong relationships with mutual aid and emergency response organizations at the local, regional and global levels.

Hess’ international oil spill response needs are supported by our partnership with Oil Spill Response Limited (OSRL), an industry funded cooperative. Our domestic needs for oil spill response are supported by the Marine Spill Response Corporation, Clean Gulf Associates, the Sakakawea Area Spill Response Cooperative, Tri-State Bird Rescue and Research and the Wildlife Center of Texas. Hess representatives serve on the board of directors of OSRL and on the technical operations committee of Clean Gulf Associates, a nonprofit oil spill cooperative that supports the Gulf of Mexico.

Our international subsea well control preparedness and response capabilities are supported by Wild Well Control. In the Gulf of Mexico, we are members of Marine Well Containment Company (MWCC), we serve on its executive committee and a senior member of our environment, health and safety team is seconded to serve as the MWCC’s Health, Safety and Environment Officer. Both Wild Well Control and MWCC provide well capping, containment and dispersant capabilities, as well as equipment and personnel mutual aid.

We contribute to the Ipieca Oil Spill Working Group in support of our international assets. We are also a member of the Oil Spill Emergency Preparedness and Response Subcommittee of the American Petroleum Institute (API). In addition, we participate in Area Planning Committee meetings for Regions 6 and 8 of the EPA.

We track LOPC events through our incident reporting system by size and material, and we report spills in accordance with applicable industry and regulatory guidance. We also use leading and lagging indicators to monitor LOPC performance and continue to include LOPC performance in our AIP.

In 2024, our AIP included a target to maintain our 2023 LOPC rate, with a stretch target of a 10% reduction year over year. We surpassed our 2024 LOPC stretch target with a rate of 0.15, a 48% reduction compared with 2023.

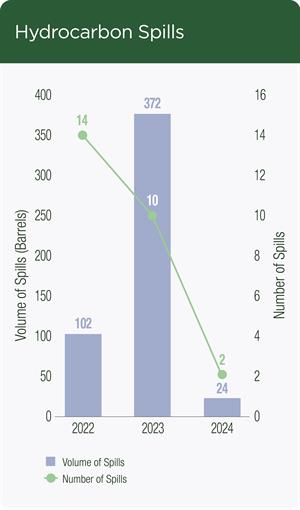

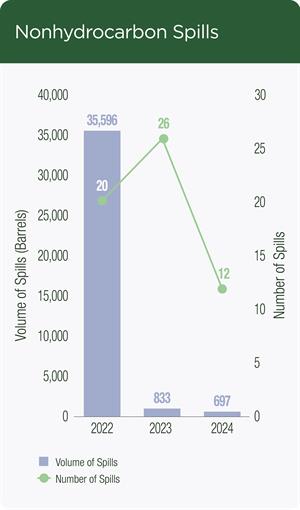

In our sustainability reporting, we disclose hydrocarbon spills based on Ipieca’s Sustainability Reporting Guidance for the Oil and Gas Industry, which includes spills greater than one barrel that reach the environment. We use this same threshold to report nonhydrocarbon spills.

In 2024, we experienced two hydrocarbon spills totaling 24 barrels, down from 10 spills and 372 barrels in 2023. We also experienced 12 nonhydrocarbon spills totaling 697 barrels, down from 26 spills and 833 barrels in 2023. In all instances, we isolated the source and took corrective actions. Additional long term remediation activities are being implemented at the affected sites where appropriate.

We carried out a range of programs focused on spill prevention in 2024. To address spills that result from corrosion and integrity issues, we further refined our inspection and surveillance programs. For example, in the Bakken we advanced implementation of enhanced, real time, remote monitoring systems for equipment, including integrity critical equipment, that tracks alignment with applicable operating parameters to help us identify and prioritize maintenance planning and response. We performed in-line inspections; close interval, soil to pipeline gradient cathodic protection surveys; and satellite remote sensing. We also renewed mitigation efforts to protect pipeline equipment from residual fracturing proppants that can impact reliability and integrity. In addition, we continued to enhance the range of key performance indicators (KPIs) that we use to track performance internally and to increase internal transparency and reporting.

We continued a multiyear effort through API’s Pipeline Safety Management System group to implement API Recommended Practice 1173, a best practice in pipeline safety. In 2024, we continued our quarterly steering committee meetings to drive implementation of API 1173 and contracted a third party auditor to conduct assurance of our implementation.

In 2024, we also began conducting a bridging exercise between API 1185 – a recommended practice on pipeline public engagement – and our stakeholder planning and engagement process.